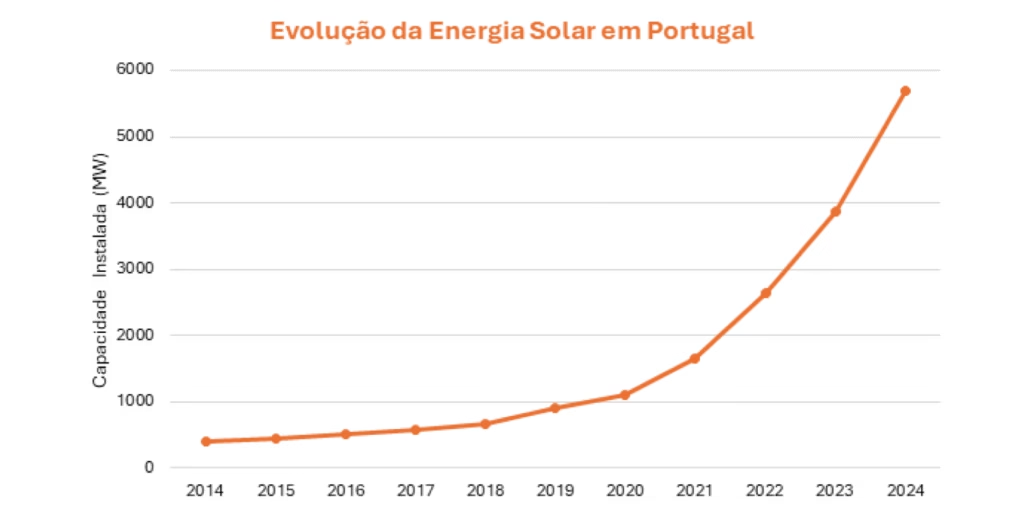

Despite the significant growth in installed capacity in Europe and Portugal in recent years.

Structural challenges such as the modernization of electrical infrastructure, efficient grid integration, and bureaucratic hurdles still impose barriers to the sector’s full development.

The success of large-scale solar park expansion depends on the ability to overcome these challenges.

To achieve this, it is essential to adopt innovative technological solutions and a strategic approach in their implementation.

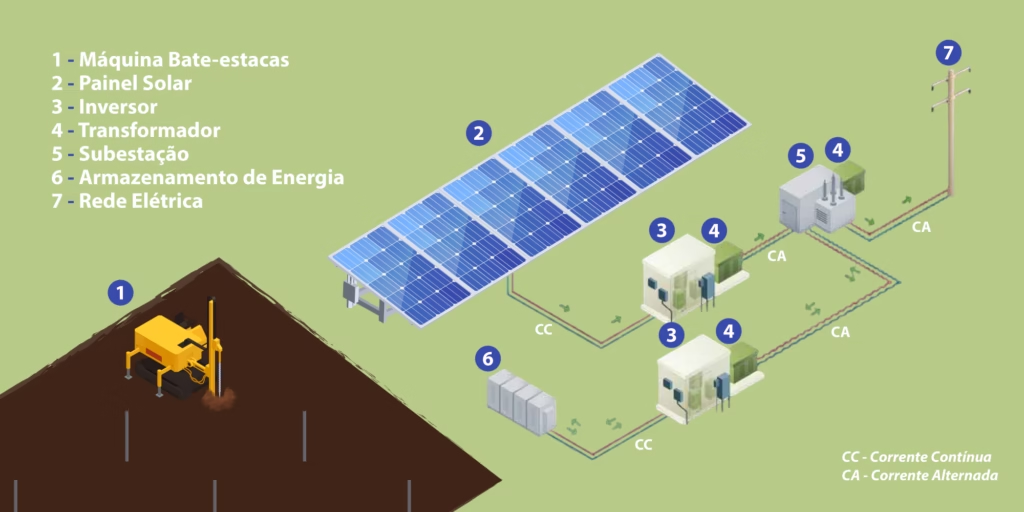

PILE-DRIVING MACHINES

Pile driving is a crucial step in constructing a solar farm, ensuring the structural stability of photovoltaic modules.

To achieve precise and efficient installation, it is essential to use pile‑driving machines with high mechanical robustness and advanced technology, capable of adapting to site‑specific ground conditions and climate.

A key part of these machines is their hammer. Solar pile‑driving machine hammers operate using a constant weight on the pile, guided by a framing structure that keeps the tool aligned. Once in position, the suspended weight is released downwards, assisted by a hydraulic system that exerts pressure into the ground to drive the pile into its installation point.

Pile‑driving machines must be capable of operating across different soil types and complex topographies, adjusting driving force and depth according to project requirements. The incorporation of advanced control and automation systems not only optimizes performance but also reduces installation deviations, ensuring greater precision and uniformity in pile fixing.

Beyond operational efficiency, minimizing environmental impact is critical when selecting equipment. Modern models are designed to minimize vibrations and operate with low noise levels, making them ideal for installations near sensitive areas.

Real‑time monitoring and intelligent automation allow instant adjustments, reducing execution time and operating costs, while also increasing safety.

The success of solar farm foundations directly depends on the quality and technology of the applied equipment, ensuring a solid and durable structure to cope with operational challenges throughout the project lifecycle.

Pile‑driving machines can install a ground‑mounted solar system in just a few minutes for 10 kW systems. Experts estimate that using a pile‑driving machine can save up to 30 percent of ground‑mounted installation costs.

PHOTOVOLTAIC MODULES

Modules or solar panels are the central element of solar power generation, converting solar radiation into electricity via semiconductor materials.

Silicon is the most widely used semiconductor in solar cell technology, but cells can also be made from organic materials or a combination of inorganic elements such as gallium arsenide or cadmium telluride. As research and solar cell technology have evolved, new semiconductor materials and manufacturing methods have emerged.

This technological progress has enabled the production of panels with distinct technical characteristics, tailored to each project’s specifics. This evolution is typically categorized into three distinct “generations” of solar cells:

1st Generation

Monocrystalline (Mono‑Si): Offering higher efficiency, these panels use homogeneous silicon cells a allowing higher power density and better performance in low irradiance conditions. They have lower thermal coefficients a reducing losses in high‑temperature environments.

Polycrystalline (Poly‑Si): Less efficient than monocrystalline cells but cheaper to produce. Due to crystal structure, they exhibit lower efficiency in high temperatures and greater degradation over time.

2nd Generation

Bifacial: Capable of absorbing radiation on both sides a increasing energy generation, especially on reflective surfaces or high‑albedo ground. When paired with tracking systems, they can deliver 20‑30 percent efficiency gains compared to conventional modules.

HJT (Heterojunction Technology) and TOPCon (Tunnel Oxide Passivated Contact): Emerging technologies combining crystalline silicon with thin amorphous silicon layers, providing efficiencies above 22 percent and lower degradation rates.

3rd Generation

Organic Solar Cells a Perovskite Solar Cells a Dye‑Sensitized Solar Cells a Quantum‑Dot Solar Cells a and Tandem Solar Cells.

As solar cell technologies continue to advance, they will fundamentally reshape how we produce and use electricity. From a silicon‑dominated market to emerging third‑generation innovations, the future of solar cells looks promising. Improvements in key factors such as efficiency a stability a and sustainability are essential to realize their full potential. If progress continues on the right track, solar energy could not only meet our growing energy needs but also lead us toward a cleaner and more sustainable future.

STRING INVERTERS

String inverters are essential components in solar farms, converting the direct current (DC) generated by photovoltaic modules into alternating current (AC) for grid injection.

Choosing the appropriate inverter directly influences system energy efficiency and reliability, impacting overall farm production.

High‑quality inverters provide optimized MPPT (Maximum Power Point Tracking) management, maximizing energy output even in variable irradiance conditions. Additionally, the availability of different power ratings offers flexibility in system sizing across varying project scales.

Remote monitoring integration enables real‑time diagnostics, facilitating fault detection and performance optimization. Inverters equipped with advanced communication technologies allow proactive management, minimizing downtime and enhancing solar farm operational efficiency.

TRANSFORMERS FOR SOLAR FARMS

A solar transformer, also known as a photovoltaic (PV) transformer or PV step‑up transformer, is a critical component in solar power infrastructure.

Its main function is to facilitate efficient generation and distribution of electricity produced by solar panels.

Transformers play a pivotal role in integrating photovoltaic generation with the electrical grid by converting energy from solar modules into voltage levels suitable for distribution. A solar transformer steps up the AC output from inverters. Solar panels produce DC electricity, which inverters convert to AC.

In solar farms, medium‑voltage transformers elevate the AC voltage generated by inverters, reducing losses and optimizing electricity transmission.

The inverter’s AC output normally must match the grid’s voltage level to be transmitted efficiently. This ensures generated electricity integrates seamlessly with the grid infrastructure, enabling use by connected consumers and businesses.

Selecting the appropriate transformer should consider key parameters such as energy efficiency, no‑load and load losses, thermal capacity, and grid compatibility. Moreover, the intermittent nature of photovoltaic generation requires transformers designed to handle load fluctuations without compromising grid stability.

Transformers specifically designed for photovoltaic applications feature optimized cooling systems, high‑insulation materials, and compact designs for easier installation in limited‑access areas. Correct specification not only ensures operational efficiency but also reduces maintenance costs and extends the electrical infrastructure’s lifespan.

Additionally, solar transformers ensure the stability and reliability of electricity supply from solar farms. They help maintain AC quality according to regulatory standards and grid operator requirements, including voltage levels a frequency a and synchronization with the grid.

ENERGY STORAGE

Energy storage in batteries has emerged as a key technology to support the transition to a more sustainable future. As solar energy becomes increasingly prevalent, energy storage becomes ever more critical to stabilize the electrical grid.

The grid must be balanced in real time to ensure frequency and voltage remain within safe limits.

Storage systems support grid stability by providing fast response in frequency control markets. Frequency measures how quickly alternating current (AC) changes direction and must stay within a narrow range of 50 or 60 Hz to ensure grid stability. Deviations can lead to power outages and equipment damage. When energy is excessive on the grid, the battery is charged. When energy is scarce, the battery supplies energy to the grid, helping maintain frequency within safe limits.

Integrating storage systems into solar farms allows maximum utilization of generated energy, reducing waste and improving grid stability.

Lithium‑ion batteries, currently the dominant technology, offer high efficiency, fast response, and long lifespan, while other solutions such as flow batteries and supercapacitors are gaining ground in specific applications.

MODULAR AND PREFABRICATED SUBSTATIONS

The growing demand for agile and efficient solutions has driven the adoption of modular and prefabricated substations in large-scale photovoltaic projects.

These compact units are designed to optimise the installation, operation, and maintenance of electrical infrastructures. This significantly reduces commissioning time and associated costs.

Modular substations can integrate transformers, medium and low voltage switchboards, protection systems, and remote control. This enables centralised control of the generated energy.

Moreover, their modular and transportable design allows easy adaptation to different network configurations. It also allows rapid expansion according to project needs.

Another advantage of these substations is their high resistance to adverse environmental conditions. They are designed to withstand extreme temperatures, high humidity, and dust. This guarantees safety and operational reliability over the long term.

The use of these infrastructures also contributes to the standardisation of engineering and maintenance processes. It facilitates component replacement and reduces downtime during interventions.

The strategic choice between conventional transformers or those integrated into modular substations should be based on the solar park size. It should also consider grid connection requirements and operational efficiency goals. This ensures maximum performance in energy conversion and distribution.

CONCLUSIONS AND FUTURE PERSPECTIVES

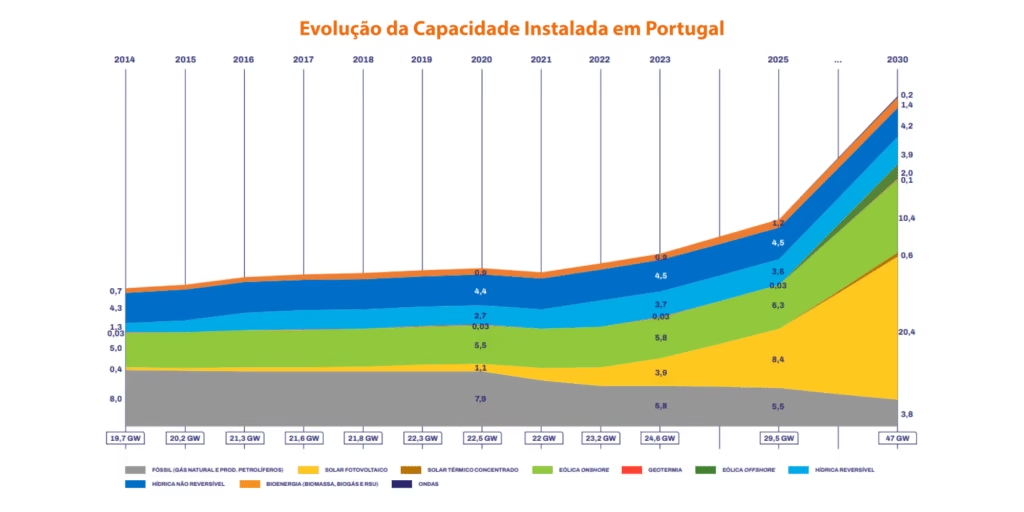

The rapid growth of solar energy in the Iberian Peninsula is not just a reflection of the global energy transition. It is also a concrete opportunity for investment and innovation.

Portugal and Spain have consolidated themselves as strategic markets for photovoltaic expansion in the European Union.

They are driven by ambitious decarbonisation targets and commitment to sustainability. With forecasts to reach 20.8 GW (Portugal) and 76.3 GW (Spain) of installed capacity by 2030. Large-scale solar parks have become essential to ensure the security and stability of the energy supply.

The updated National Energy and Climate Plan 2021-2030 (PNEC 2030) forecasts significant solar capacity growth. The target is to reach 20.8 GW by 2030, about four times higher than the 2024 level (5.7 GW).

However, the sector’s expansion speed depends directly on the implementation of efficient and well-designed infrastructures. The exponential growth of installed capacity requires technical solutions that ensure secure connectivity, operational efficiency, and long-term economic viability.

Without adequate infrastructures like support systems, electrical substations, and optimised distribution networks, solar energy’s potential may be limited. These limitations include energy losses, grid connection restrictions, and regulatory challenges.

Thus, the current moment demands strategic decisions based on innovation and the quality of the equipment used. As investments in solar energy increase, the players that choose the best technological solutions will have a clear competitive advantage, ensuring greater profitability, safety, and efficiency in the operation of their projects.

The future of renewable energy is underway, and those who know how to seize this growth with a structured approach will be at the forefront of the solar revolution in Europe.