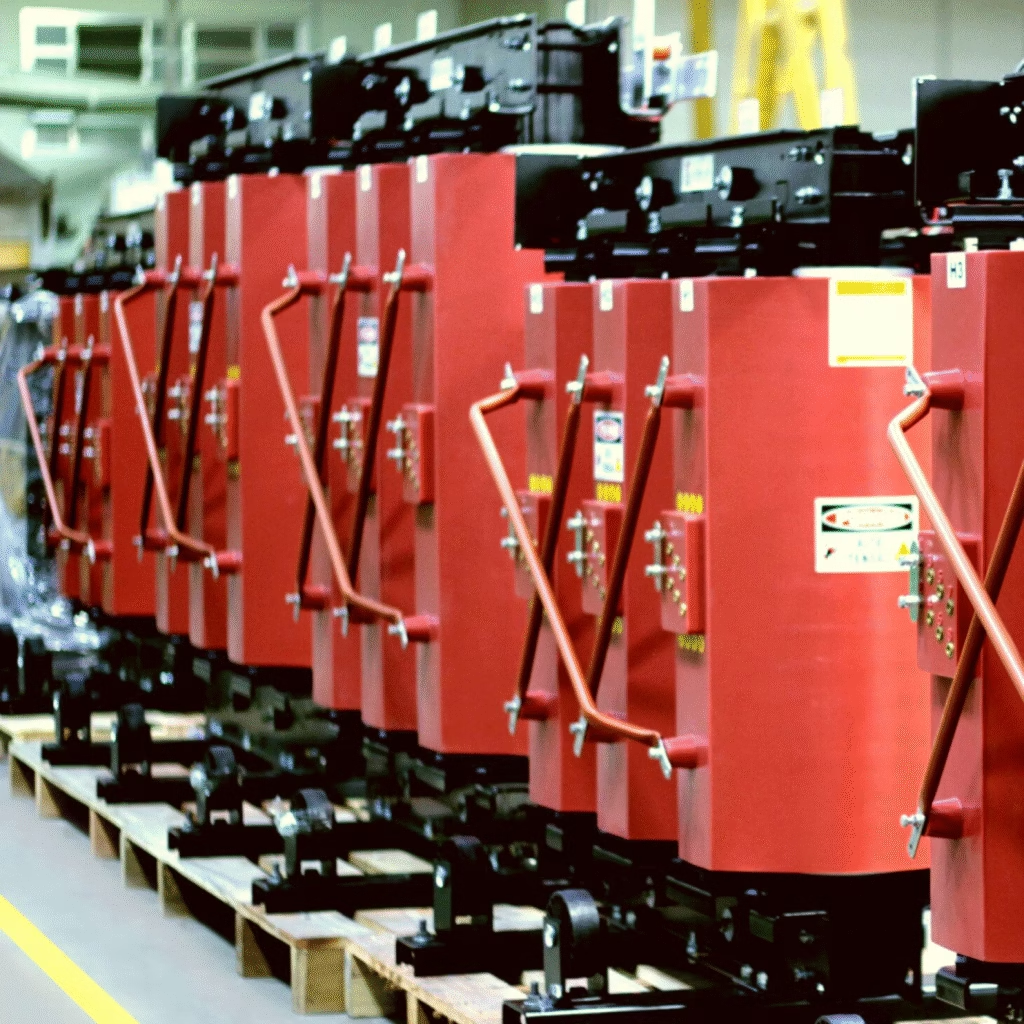

DRY‑TYPE TRANSFORMERS

Dry-type transformers, also known as cast resin transformers, have at least one of the windings encapsulated in epoxy resin in an autoclave mould under near-absolute vacuum. The second winding may also be cast in thermal class H.

Thanks to technological advances in recent years, these transformers have achieved a high level of reliability. They are manufactured according to the following standards: E2 (humid environments); C2 (thermal resistance); and F1 (fire resistance).

They can also be produced according to stricter standards: E3 (IEC 60076‑16) and C4 (GOST‑R).

As they are entirely built using insulating and flame-retardant materials, they eliminate the risks associated with fire, as well as the emission of toxic gases or harmful substances.

These transformers are not subject to the restrictions applicable to equipment with flammable fluids, making them ideal for applications in enclosed spaces, public areas, sensitive zones, or demanding environments.

TRANSFORMATION SUBSTATIONS

Medium/low voltage (MV/LV) transformation substations are designed to operate in both indoor and outdoor environments, depending on the types and dimensions of the MV and LV panels used. Each substation consists of three main compartments: MV compartment, transformer compartment, and LV compartment.

Depending on the project requirements, the substation may include only the compartments with MV panels. These transformer stations can be built using monoblock concrete, prefabricated concrete, galvanised metal sheet, or aluminium sheet.

For concrete stations, self-compacting concrete of class C35 is used. In metal substations, galvanised steel sheets with 2 mm thickness and 275 g/m² are used for doors, ventilation grilles, and coverings.

METAL TRANSFORMATION SUBSTATIONS

EVA metal substations are generally manufactured using 2 mm pre-painted galvanised metal sheets or aluminium sheets, which offer greater corrosion resistance.

These substations follow a common design with three compartments: medium-voltage (MV) switchgears, distribution transformer, and low-voltage (LV) panels.

This modular design allows a significant reduction in size and weight, especially when using gas-insulated switchgears (GIS). Thanks to their modular structure, they can be easily sized and manufactured to meet various requirements.

EVA metal substations can be mounted on vehicles and transported according to their dimensions. If transport as a single unit is not possible, they can be disassembled and reassembled at the destination site.

MOBILE TRANSFORMATION SUBSTATIONS

EVA mobile transformer substations can be manufactured in different configurations and dimensions to meet urgent energy needs, such as in cases of natural disasters (earthquakes, storms, floods) or to reinforce the power grid in seasonal tourist areas or regions with unstable or interrupted supply.

36 kV Mobile Substations

These MV/LV mobile substations convert energy from the medium-voltage distribution network to low voltage, with capacities up to 1,600 kVA.

Typical applications: Temporary replacement of substations under maintenance or failure; and power supply in critical situations such as hospitals, clinics, rescue operations, or accident sites.

Main components: Medium Voltage Compartment; Transformer Compartment; and Low Voltage Compartment (LV distribution panels).